Today we’d like to introduce you to Eric Eggemeyer.

Hi Eric, so excited to have you with us today. What can you tell us about your story?

Building and designing with natural stone has been a passion of mine for as long as I can remember. I have always been involved in building and construction, even as a child. After studying architecture and engineering in college, I’ve had many construction industry jobs and learned a great deal of knowledge throughout my different trades. My fond memories are managing a demolition company and Austin tearing down many of the buildings where the multi-level buildings are built today. I also was the plant manager of a stone quarry in West Texas. This allowed me to be introduced to natural limestone and provided me with hands-on experience and fabricating and designing a multitude of dimensional limestone materials. Throughout the mini projects of my life involving construction, I’ve always wanted to find a way to provide a quality Masonry product to the industry that would not only look like natural limestone but also be affordable and practical and used within the industry. I discovered a product out of Australia that has been used for dozens of years within the construction industry. I’ve been producing reconstituted limestone blocks around the world for many years but not until late in the US market. With the rising cost of lumber, sheetrock, plywood, and insulation, the construction cost of commercial and residential properties have skyrocketed. Reconstituted limestone block is an economical way for The end-user to have the feel and look of natural lime stone at a major decrease in expense. I am passionate about this product and excited to bring it to the hill country for the first time.

We all face challenges, but would you describe it as a relatively smooth road?

It has been nothing but roadblock after roadblock. I would have to say anyone trying to start a new business concept in today’s market must be absolutely insane or in desperate need of mental help. I’ve been working on this for two years now, and every obstacle I run across seems to be roadblock after roadblock. With the rising cost and unpredictable shortages of equipment and parts, I’m surprised anyone can still stay in business. Probably the most challenging lesson to learn during this process is from the lenders. Don’t ever trust just one lender. Even if they think your product is the best bet, they’ll end up pulling away completely. It’s better to involve many lenders in the beginning and hope that maybe one will end up going with you.

Thanks for sharing that. So, maybe next, you can tell us more about your business.

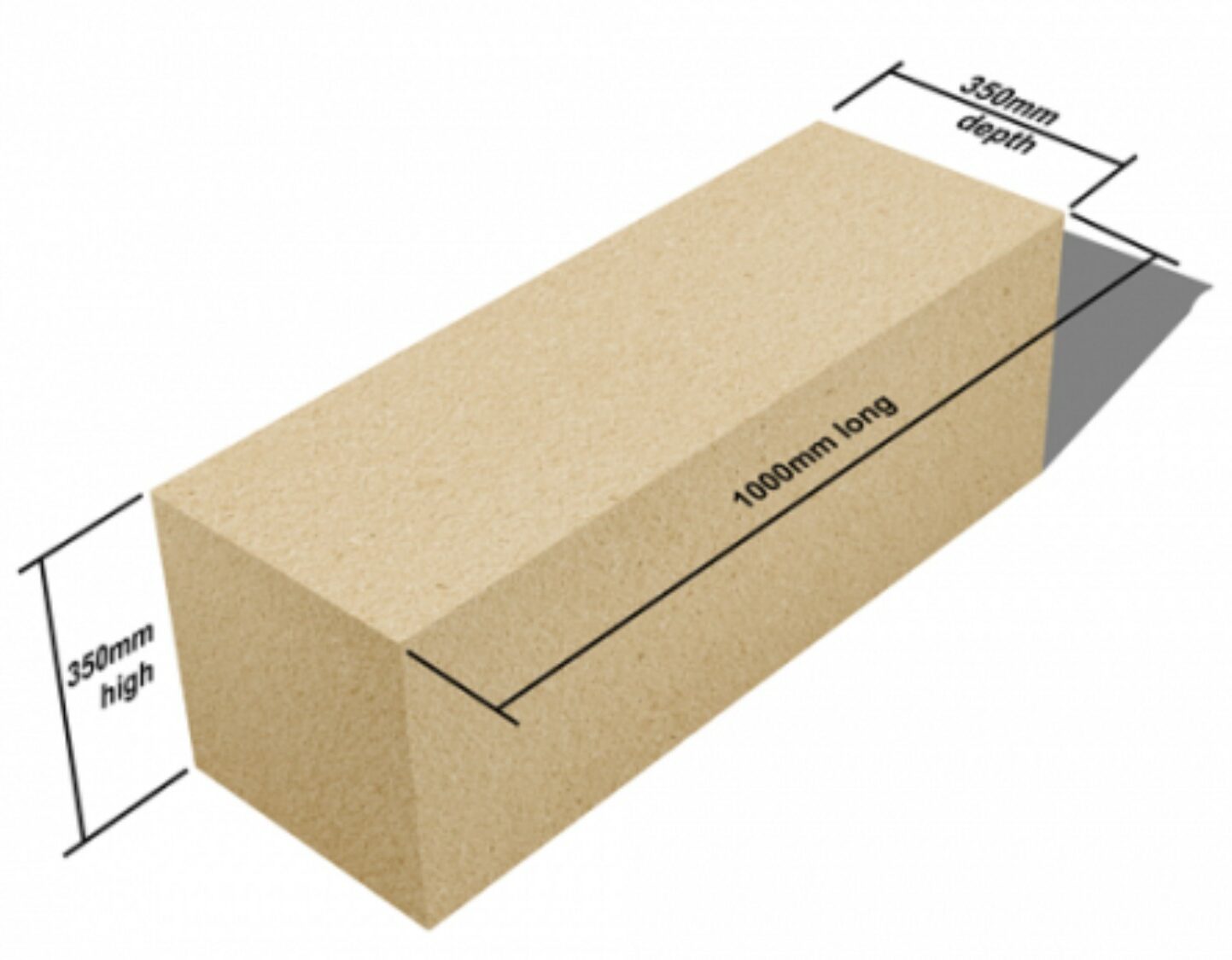

Fenton Stoneworks is a precast block manufacturing facility offering dimensional reconstituted limestone blocks to the hill country. Our facility is new to the hill country and offers dimensional reconstituted limestone blocks to the building and that landscape industry. Our blocks are the first, so they’re kind to be manufactured in the hill country and can be used for many projects. Our blocks can be used for residential and commercial construction of buildings and retaining wall purposes from the small backyard slope to large State Highway projects. The price per block is very affordable and, compared to other building techniques, makes perfect sense for any project. With our reconstituted limestone blocks, there is no need for two-by-fours, insulation, and plywood. Our blocks are not only visually appealing; they are thermal barriers and structural components of the building. There is a 40% savings once the normally constructed wooden walls are replaced with large limestone blocks. Thinking of it as building the old fashion way. Just The beauty of stone blocks at a major reduced cost and effort.

What’s next?

Once in production, we foresee our blocks replacing the so-called butter sticks. Butter sticks are the large 2‘ x 2‘ x 5‘, 3000-pound blocks you see all over the hill country. These blocks are beautiful and 100% natural limestone. However, these blocks are generally dimensionally different. With our reconstituted limestone blocks, each block is the same and much easier to work with. Natural limestone is approximately 1800 psi, and our blocks will average 2800 psi making for a much stronger masonry component over natural limestone. Our blocks are also stronger as they are fabricated with the addition of cement and various other plasticizers.

Pricing:

- Large blocks approximately $48 each